Bluelight Hoisting Belt

- Bluelight

- China

- 15 days

- 2 million meters

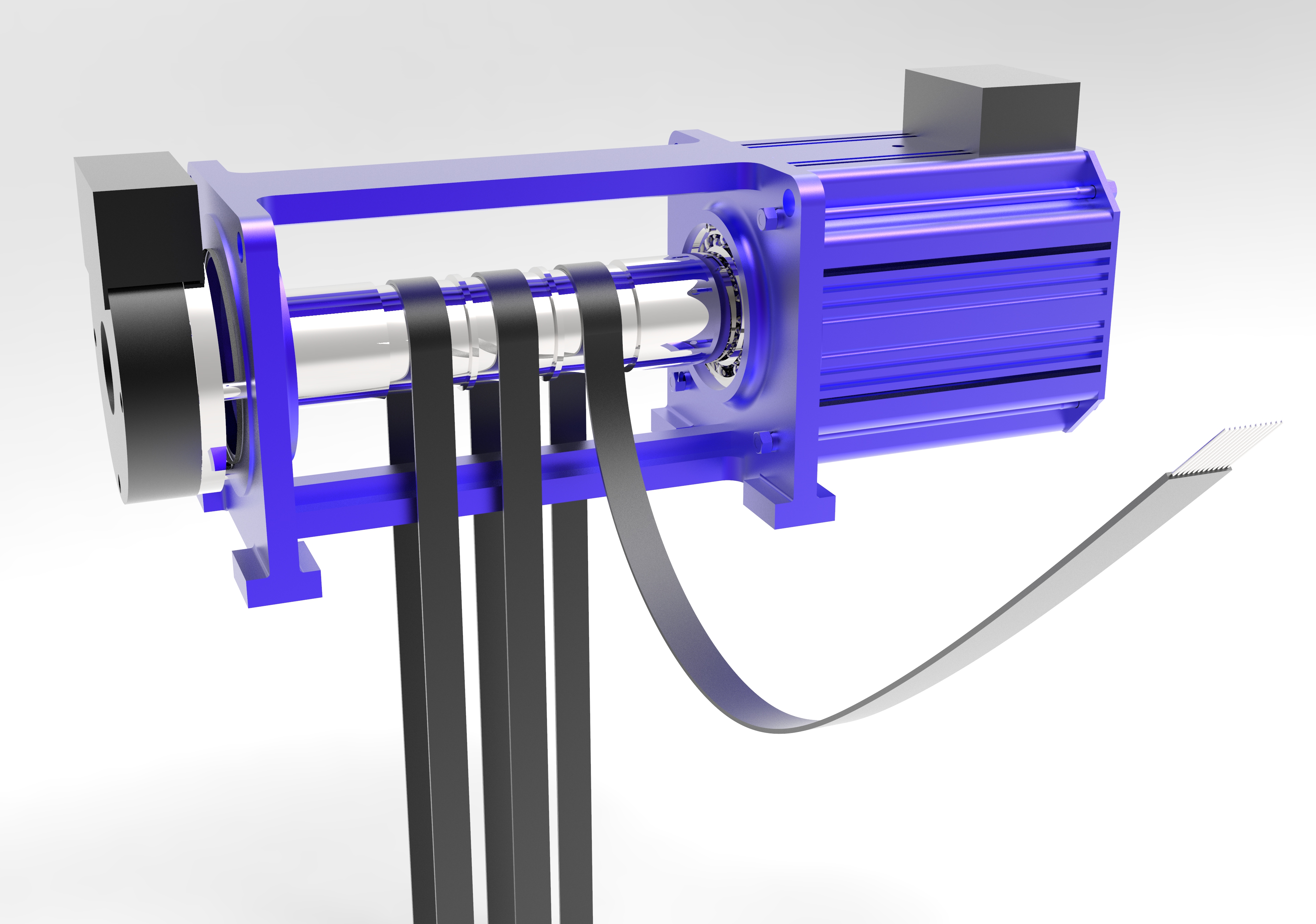

1.Elevator belt have double support structure,reliable structure ,and better performance

2.Elevator belt configured with shaft brake of low noise and compact structure.

3.Elevator belt use self-sealed bearings,maintenance free.

4.Elevator belt have electromagnetic structure optimization,smooth running and low noise.

SYLG-EB- Elevator belt

Specifications for Elevator belt

Model | 32kN | 34kN | 43kN | 64kN |

Thickness | 3.0 | 3.3 | 3.3 | 3.0 |

Width | 30 | 25 | 30 | 60 |

No. of Steel Core | 3000 | 8 | 10 | 24 |

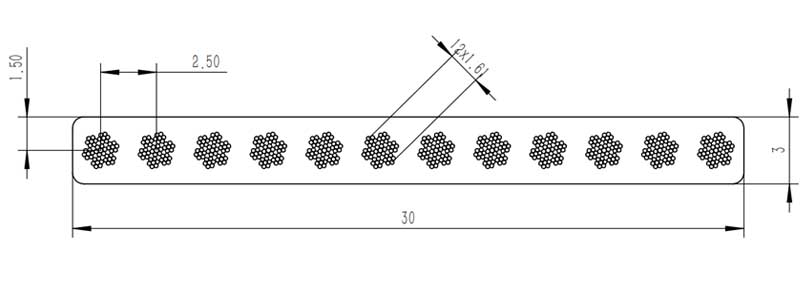

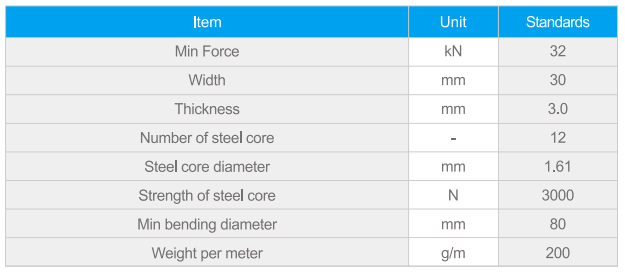

32KN Elevator belt

Elevator belt suitable for low to medium floor passenger elevators,villa elevators and most elevator applications .

Elevator belt have 30mm width ,common size in the market.

Elevator belt using 2:1 and 1:1 roping ratio.

Elevator belt with 12 hyperfine steel cores and only 1.6mm diameter.

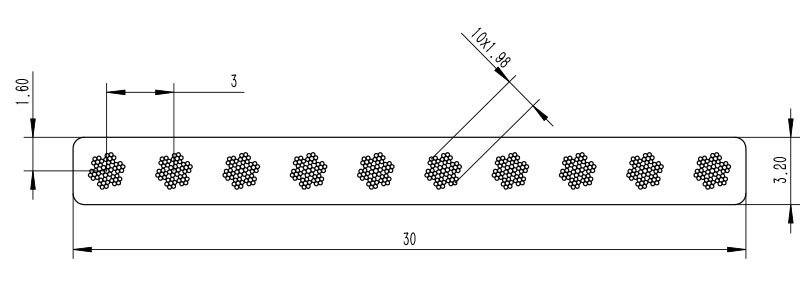

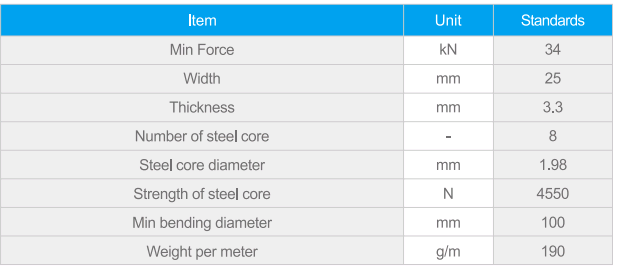

34KN Elevator belt

34KN elevator belt suitable for low villa elevator.

34KN elevator belt is lighter,stronger and more economic.

34KN elevator belt with 2:1 roping ratio.

34KN elevator belt with 25mm width applications.

34KN elevator belt with 8 high precision steel cores with 1.98mm diameter.

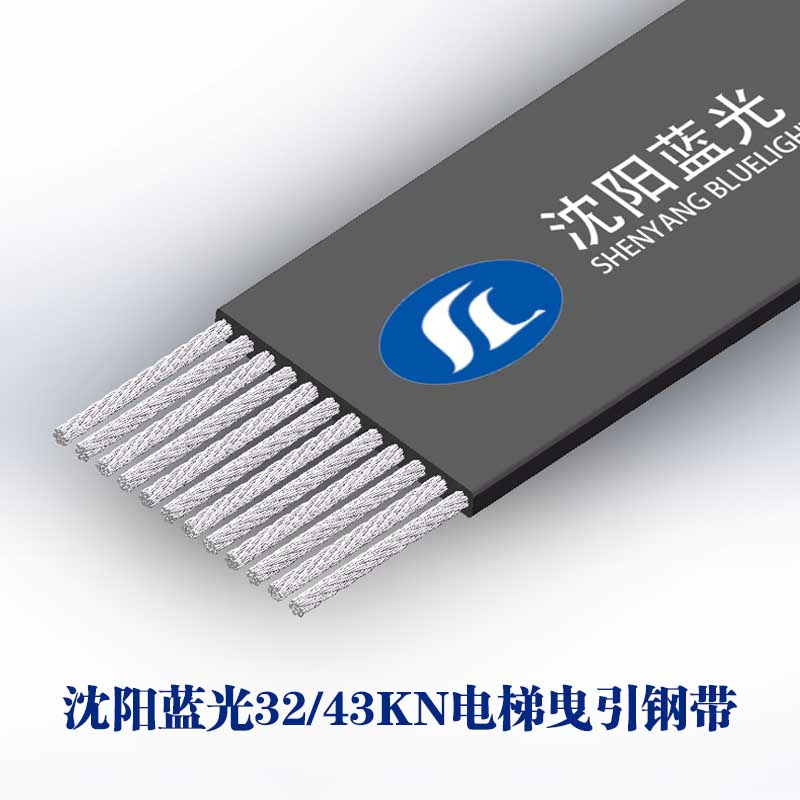

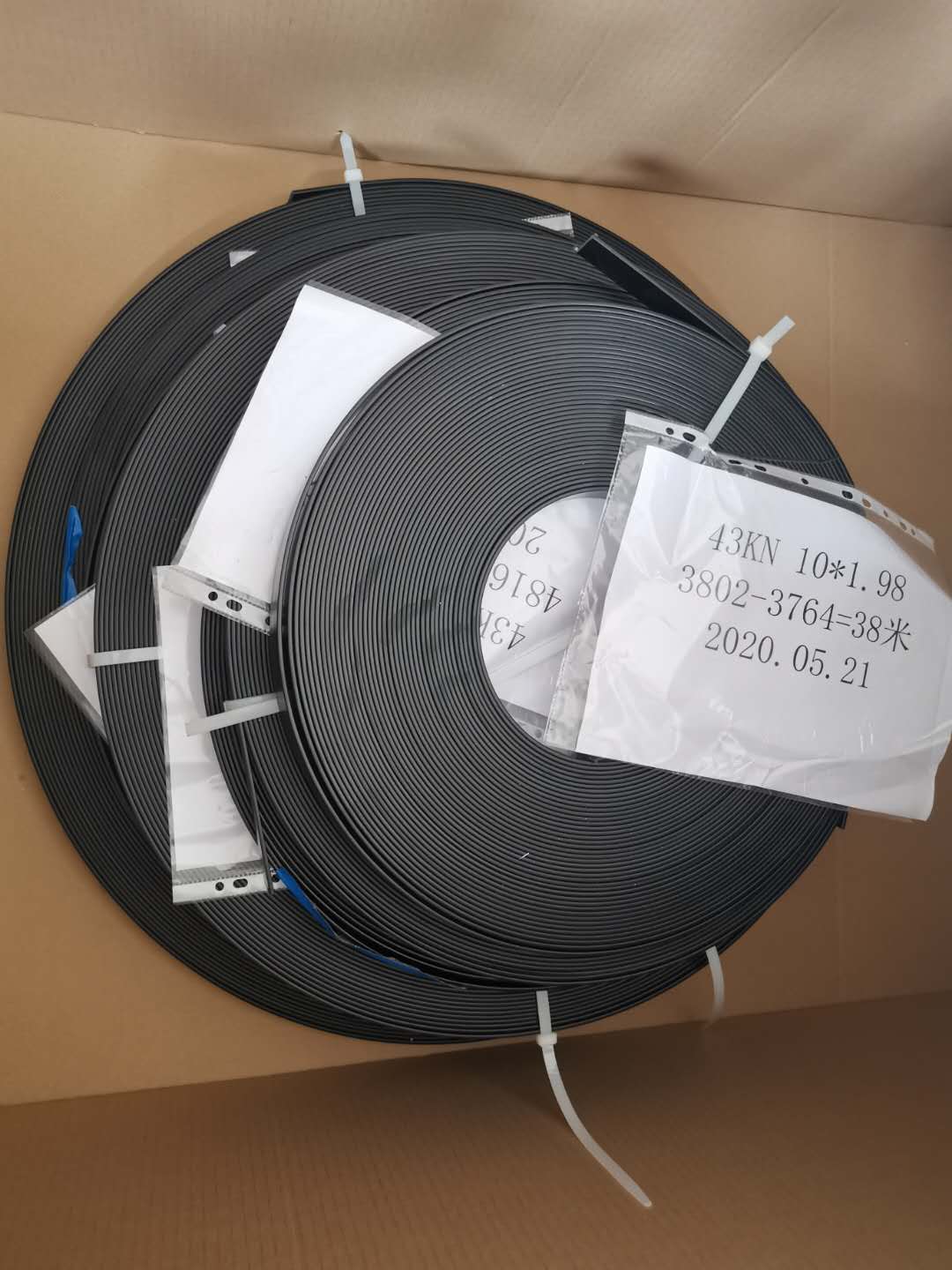

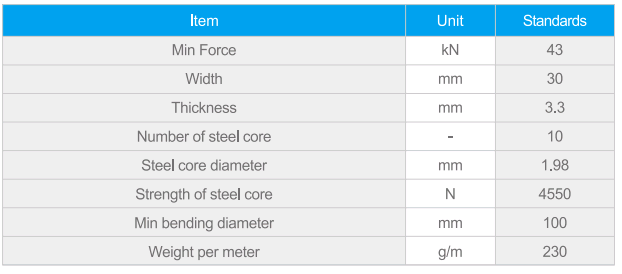

43KN Hoisting belt

43KN hoisting belt suitable for commercial elevators ,medium to high floor passenger elevators and heavy load villa elevators.

43KN hoisting belt with 30mm width,common size in the market.

43KN hoisting belt have 10 high precision steel cores with 1.98mm diameter.

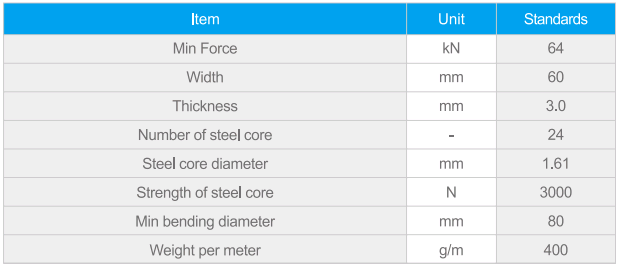

64KN Hoisting belt

Elevator hoisting belt suitable for freight elevators,bed elevators and heavy load passenger elevators.

Elevator hoisting belt with 60mm width,requires high installation quality.

elevator hoisting belt have 24 hyperfine steel cores with only 1.6mm diameter.

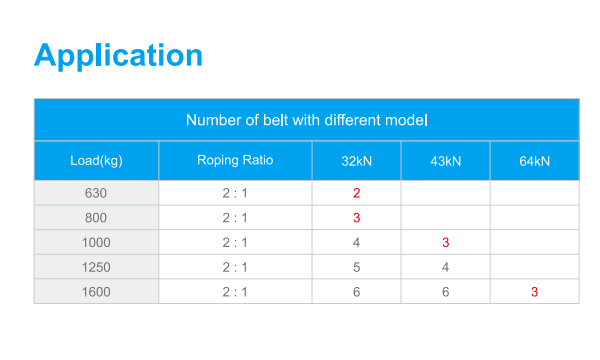

Our elevator steel belt calculated by safety factor of 12.

Elevator steeel belt nominal strength is counted by minimum breaking force with safety margin.

The elevator steel belt using 3 belts is the most economic efficiency.

Features

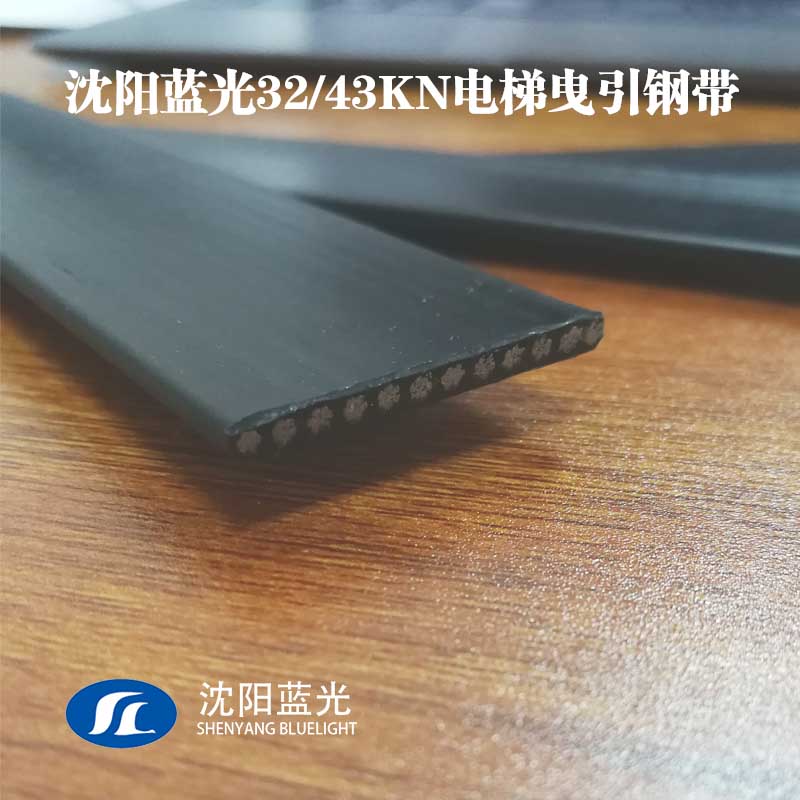

Our elevator steel belt use BASF Elastogran high hardness TPU, so it has excellent mechanical and chemical features.

All elevator steel belt using world class technic to produce high prevision galvanized no joint steel rope, with uniform shaping, high fatigue durability and corrosion resistance.

The elevator steel belt have great concentration on surface treatment developing, the equivalent friction coefficient is more stable, and capable of handling more complicated working conditions.

Online contour scanning system, real-time monitoring of external dimensions to ensure the same quality of every meter of elevator steel belt

Elevator steel beltunder strict fatigue test during development process. Life time is more than 10 million times bending test.

For the elevator steel belt we have Symmetrical design, no need to consider the front and back sides, uniform material, no risk of cracking;

The surface of the hoisting belt is coated with glue, and its pulling force is the highest in the industry;

We have production line for the modernization project to replace gen2 belt .which ensures our hoisting belt have stable and controllable quality;

The produced for hoisting belt can fully replace the products of OTIS and have the same quality;

The annual production capacity of hoisting belt is 2 million meters ,and our R&D center has invested full sets of tseting equimpent for elevator traction belt;

Bluelight Advantages

Founded in 1989, a technology company with the highest technical strength and strong R&D team with more than 30 national patents.

The only manufacturer in China to produce both control systems and PM traction machine.

Developed and produced the first PM Traction Machine in China. In 2006, established a joint venture with industry giant OTIS Elevator. Bluelight products have OTIS quality, strict quality control, and 100% inspection before delivery.

Professional team with more than 20 years of export trade experience provides you the most professional guidance and advice.

Related Products