elevator belt

-

Hot

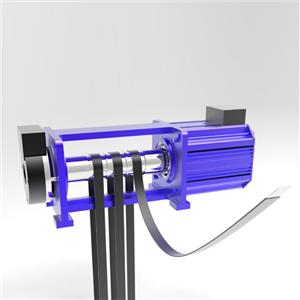

Bluelight SJT-BRM Series Belt Detector

1. BlueLight elevator steel belt detector can be installed in elevators that use steel belt traction,and can continuously monitor the safety status of the steel core inside each steel belt. 2. This elevator steel belt detector consists of three parts: a detection host, an elevator steel belt head connector, and an elevator steel belt end shorting connector. 3. The entire steel core of each elevator steel belt is connected in series through the head connector and end short connector, and electrical excitation is provided to monitor the steel belt's electrical characteristics.

Email Details -

Hot

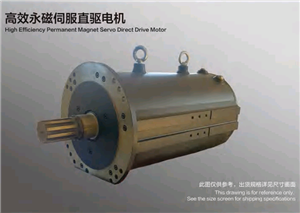

Bluelight Hoisting Belt

1.Elevator belt have double support structure,reliable structure ,and better performance 2.Elevator belt configured with shaft brake of low noise and compact structure. 3.Elevator belt use self-sealed bearings,maintenance free. 4.Elevator belt have electromagnetic structure optimization,smooth running and low noise.

Email Details