BLM Inner Rotor series ultra-thin semi-direct drive oilfield motor

- Bluelight

- China

- 80000 units / year

1. Easy to install and modify.

2. No transmission belt, maintenance free and more reliable.

3. High effeciency and energy saving, semi-direct drive reduces working cost.

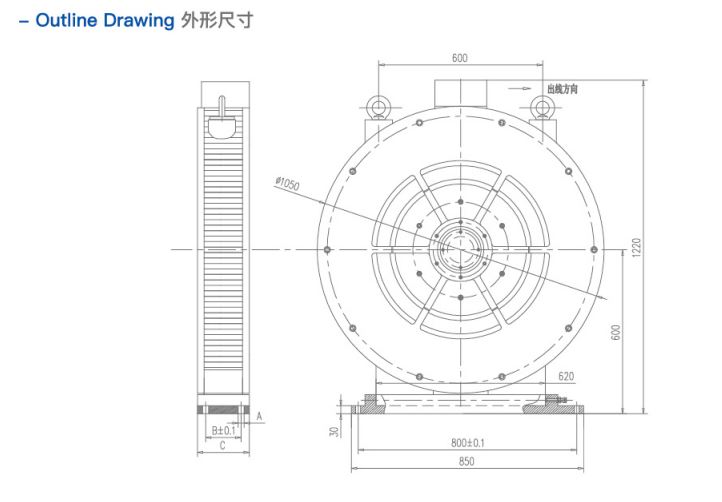

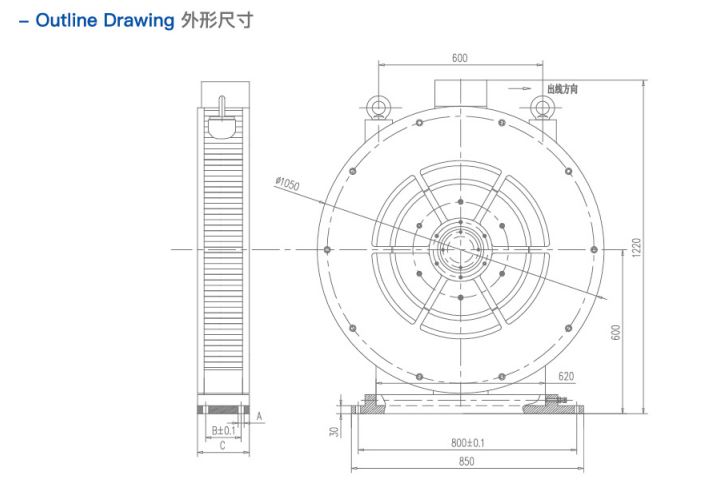

4. Optimise structure of ultra-thin design, small size for less installation space.

Inner rotor ultra-thin semi-direct drive oilfield Motor

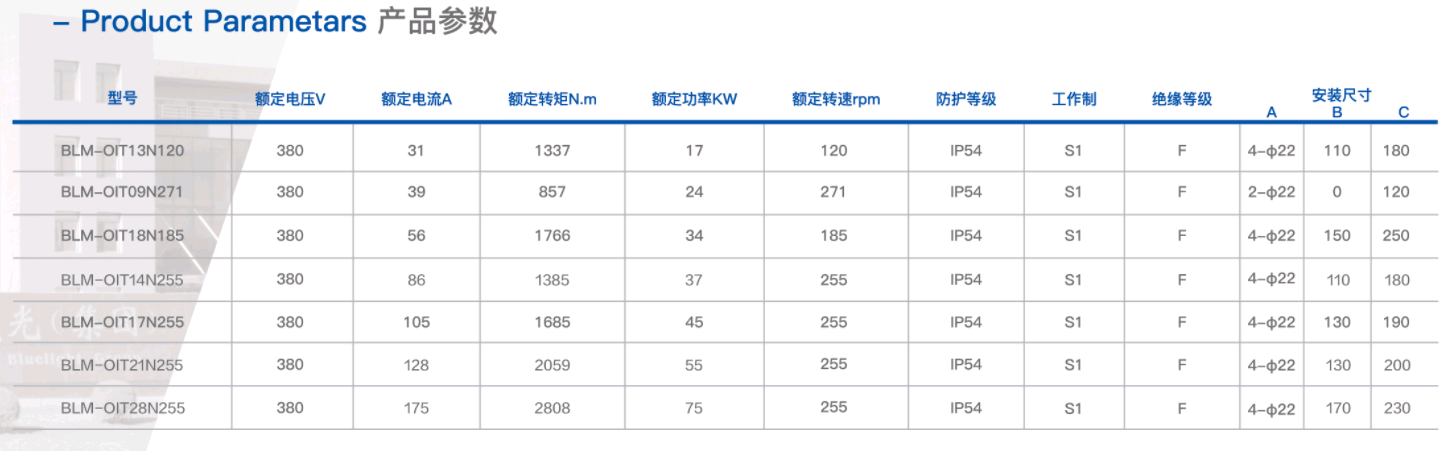

Model: BLM inner rotor Permanent Magnet Synchrounous Ultra-thin Semi-direct Drive Motor for oil well pumping jack,

BLM inner rotor series ultra-thin semi-direct drive oilfield motor is specially designed for the beam pumping unit of our company,it cancels the belt drive and solves the problems of the traditional pumping unit adopting the belt transmission efficiency and the belt easy to wear and affect the service life,the direct connection structure is reasonable in design,compact in layout,convenient in field modification,cost saving,improved transmission efficiency,reduced floor space ,and improved adaptability and waterproofing requirements of the motor in outdoor open air work.

Features

1. Easy to install and modify.

2. No transmission belt, maintenance free and more reliable.

3. High effeciency and energy saving, semi-direct drive reduces working cost.

4. Optimise structure of ultra-thin design, small size for less installation space.

More details, please download Bluelight catalogue.

Bluelight Partners

Other products you would be interested (Please check "Product" to find more details)

Bluelight Advantages

Founded in 1989, a technology-based company with the highest technical strength and strong R&D team with more than 30 national patents.

The only manufacturer in China to produce both control systems and PM traction machine.

Developed and produced the first PM Traction Machine in China. In 2006, established a joint venture with industry giant OTIS Elevator. Bluelight products have OTIS quality, strict quality control, and 100% inspection before delivery.

Compared with the same industry, bluelight PM traction machine has higher material grade, higher quality materials and more strict inspection.

Professional team with more than 20 years of export trade experience provides you the most professional guidance and advice.

Comprehensive certificates, such as CE, KTL, LIFTINSTITUUT, etc.

24-hour professional English technical consultant, free after-sales service and technical training.

Three factories (locates in Fushun, Nanxun, Foshan) have sufficient production capacity, guaranteed delivery time and convenient port delivery to save cost for you.

Shenyang Bluelight has a strong production capacity and short delivery time ,the dalivery date of standard elevator integrated controller is about 3 working days,standard control board is 5 working days ,standard traction machine delivery time is 7 working days .

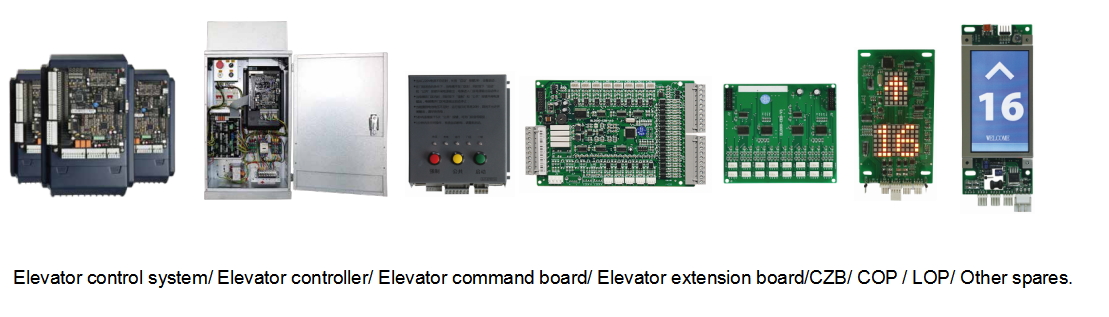

Shenyang Bluelight is the only supplier in China who owns the independent intellectual Property Rights to provide complete elevator system solutions ,from logic control,drive,traction to monitoring.