BLIUELIGHT GROUP -- SJT-WVF5-I ELEVATOR CONTROL CABINET

The elevator control cabinet is the core command and control center of an elevator system, responsible for coordinating, monitoring, and regulating all operational functions of the elevator , hoistway components, and door systems. Acting as the "brain" of the elevator, it ensures safe, efficient, and smooth vertical transportation by integrating electrical components, control logic, and communication modules.

The control cabinet executes a series of critical functions to maintain elevator performance and safet

Core Functions of the Elevator Control Cabinet

1.Call Registration & Dispatching Logic

It receives and processes hall call signals (up/down buttons on each floor) and car call signals (destination buttons inside the car). Based on preset algorithms (e.g., collective control, group control for multi-elevator buildings), it optimizes car dispatching to minimize waiting time and energy consumption.

2.Speed & Motion Control

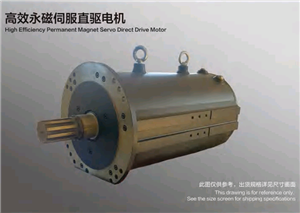

By regulating the traction motor, the cabinet controls the elevator’s acceleration, constant speed, and deceleration phases. Modern systems adopt variable frequency drive (VFD) technology to adjust motor speed precisely, reducing mechanical wear and ensuring a comfortable ride.

3. Safety Protection Monitoring

It is connected to key safety devices in the elevator system, including overload sensors, door interlocks, emergency stop switches, overspeed governors, and buffer limit switches. In case of abnormal conditions (e.g., overloading, door not fully closed, overspeed), the cabinet immediately triggers protective actions (e.g., stopping the car, locking doors, activating emergency brakes) to prevent accidents.

Based on customer needs, we have specially launched a SJT-WVF5-I ELEVATOR CONTROL CABINET with the following upgraded features:

Modular components for internal structure. Easy wiring, assembling and repairing.

Internal interface board provides easy accessibility for hoistway cable and travelling cable. The simple plug-in type connection makes wiring mistake free and save time.

Built-in over-voltage protection module to cut off power input immediately after neutral wire is broken. Ensure the safety of electric components.

Built-in power source for brake system. Provides DC brake control which is more efficient and introduces less high frequency interference, heat or noise.

Built-in DC24V switch power source, direct power output for Landing Call board, Car Board and so on. Provides up to 5A rated output current.

Separate the brake system power source from the transformer, reduce its volume and weight. Thus, the size of the cabinet is reduced about 66% than normal cabinet.

Light body design for the cabinet, minimize the amount of circuit breaker and contactor. The cabinet is wire socket groove free.